- Carbon[1]

- Chemical Product Machinery[1]

- Ceramics[1]

- Biscuits[3]

- Mixing Equipment[7]

- Filters[31]

- Home Textile Product Machinery Parts[30]

- Beverage Processing Machinery Parts[2]

- Food Processing Machinery Parts[2]

- Keyboards[1]

- Cap Making Machinery[1]

- Wire Mesh[6]

- Water Treatment[3]

- Cutting and Forming Tools[7]

- Glass Processing Machinery Parts[1]

- Pipe Making Machinery[1]

- Pressure Vessels[2]

- Packaging Machinery[1]

- Pharmaceutical Machinery Parts[1]

- Reactors[3]

- Hand Carts & Trolleys[2]

- Metal Forging Machinery[3]

- Cleaning Equipment[1]

- Mazut[1]

- Battery Packs[1]

- Contact Person : Ms. Ni Sala

- Company Name : Wenzhou Jhen Ten Machinery Co., Ltd.

- Tel : 86-577-86825175

- Fax : 86-577-86810195

- Address : Zhejiang,wenzhou,No.3 Jin'ou Road,Shacheng ,Longwan District,Wenzhou City,Zhejiang Province,China

- Country/Region : China

- Zip : 325025

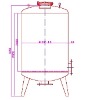

Mechanical Filter

Detailed Product Description

Working Principle:

Activated carbon filters through the carbon bed to finish filter. The activated carbon bed is composed of many particles of microporous and enormous specific surface with strong physical adsorption capacity. Water flow through the carbon bed, organic pollutants in water was adsorbed by activated carbon effectively.

Addition , activated carbon of non-crystalline part on the surface has some of the oxygen tube to allow the water through the carbon bed of organic pollutants by activated carbon adsorption . Activated carbon filters are commonly used in water treatment equipment, as a water treatment system to ensure pre-treatment to be effective before desalination to assure equipment life, improve water quality, pollution prevention, particularly after the class is to prevent the reverse osmosis membrane, ion exchange resins, etc. free oxygen toxicity than pollution.the available method of backwashing restore its adsorption capacity. The reasonable structure, easy to use, applicable to a variety of higher quality

Application :

the depth of water purification; breweries, beverage and other industries the depth of water purification treatment;

process condensate water removal, treatment, etc. In addition to organic matter; pure water, high pure water preparation process of the former treatment; industrial wastewater 3

domestic wastewater treatment such as purification.harmful substances, such as organic matter, colloids, microorganisms, oil, residual chlorine

restaurant, hotel, units, stations, terminals, industrial and mining enterprises and institutions, as a water depth of Living purification equipment. The device with the UV sterilizer supporting the use of drinking water can be used as brewing beverages, food, pharmaceutical, chemical and other

industrial water ideal for water purification equipment.

Technic parameter:1.filter speed:11-15m32.back flushing time:4-10min3.regenerate time:15-30min4.inlet water tuibidity:<=10mg/L5.outlet water ruibidity:<=3mg/L6.wipe off rate:90-96%7.back flushing intension:12-18L/S.m2

Item Model Specification Carbon Hight (mm) Flowrate (T/H) Design Pressure (Mpa) Water pressure Test( Mpa)

DN H1 H2

MF-600 600 2350 1500 1200 1.4-2.8 0.6 0.75

MF-800 800 2350 1500 1200 2.5-5.0 0.6 0.75

MF-1000 1000 2600 1500 1200 4.0-8.0 0.6 0.75

MF-1200 1200 2600 1500 1200 5.5-11 0.6 0.75

MF-1400 1400 2800 1800 1200 7.5-15 0.6 0.75

MF-1600 1600 2800 1800 1200 10-20 0.6 0.75

MF-1800 1800 2800 1800 1200 13-25 0.6 0.75

MF-2000 2000 2800 1800 1200 16-31 0.6 0.75

MF-2500 2500 3000 2000 1200 25-49 0.6 0.75

MF-3000 3000 3000 2000 1200 35-71 0.6 0.75

MF-3200 3200 3000 2000 1200 40-80 0.6 0.75